Penny Pinching Tech Tips.

+11

Truxter Fordly

Nanook

Arieldouglas

dieseldr

Brownie

DEMONSPEED

JRiggs

mpvance

Chris55

Reb Stew

RebStew

15 posters

Penny Pinching Tech Tips.

Penny Pinching Tech Tips.

I have been wanting to do a thread on ways to do stuff without breaking the bank. Now a days with the price of everything going up, real cars builders need to get back to the roots of hot rodding. Building things or fabbing up stuff on the cheap side.

When I was a teenager we drove low riders. Not cause they were cool or we bought drop spindles. We had low riders cause our springs where broken down.

We drove wagons. Long roofs now are in style. Wagons back then were not cool they were hand me downs from dad or they where cheap to buy out of the paper. Remember reading the paper to find a car?

We had rat rods! We didn't build rat rods we just could afford to fix up our junk!

We had primer on our cars. Not cause it was in style but because we couldn't afford to do all the body work and paint it.

Self tinted our windows, sometimes not the right way. I remember a cop sticking his face against my big side glass on my 67 Tempest wagon and asking me if I could see out of that tint. YES! I can! Really I couldn't. Not at all. I couldn't afford window tint for all the glass so the very back big ones I spray painted them with 97 cent black paint.

We had suede or flat color paint long before it was in style. Why? Becuse we got tire of grey, black or red primered cars. I remember trying to get ready to take the T bird to TN and was primering it. I had some red and blue paint from a guys car I painted. I tossed it in with the grey primer and we ended up with a purple suede 65 T bird.

The cars I had and most of my friends had where not hi dollar machines but they where friggin' cool! We built them on a budget and had fun doing it!

The reason for the rant is hot rodding has become such a hi dollar, gold chainer hobby. Getting back to doing the work yourself and building something cool is what it's about.

If you have any low buck ideas please post them here.

When I was a teenager we drove low riders. Not cause they were cool or we bought drop spindles. We had low riders cause our springs where broken down.

We drove wagons. Long roofs now are in style. Wagons back then were not cool they were hand me downs from dad or they where cheap to buy out of the paper. Remember reading the paper to find a car?

We had rat rods! We didn't build rat rods we just could afford to fix up our junk!

We had primer on our cars. Not cause it was in style but because we couldn't afford to do all the body work and paint it.

Self tinted our windows, sometimes not the right way. I remember a cop sticking his face against my big side glass on my 67 Tempest wagon and asking me if I could see out of that tint. YES! I can! Really I couldn't. Not at all. I couldn't afford window tint for all the glass so the very back big ones I spray painted them with 97 cent black paint.

We had suede or flat color paint long before it was in style. Why? Becuse we got tire of grey, black or red primered cars. I remember trying to get ready to take the T bird to TN and was primering it. I had some red and blue paint from a guys car I painted. I tossed it in with the grey primer and we ended up with a purple suede 65 T bird.

The cars I had and most of my friends had where not hi dollar machines but they where friggin' cool! We built them on a budget and had fun doing it!

The reason for the rant is hot rodding has become such a hi dollar, gold chainer hobby. Getting back to doing the work yourself and building something cool is what it's about.

If you have any low buck ideas please post them here.

RebStew- Scrounger's Pitbull On Nitrous

- Number of posts : 12420

Registration date : 2007-10-09

Age : 95

Location : Newport Ky

Peel & Seal is the cheap alternative to Dynamat.

Peel & Seal is the cheap alternative to Dynamat.

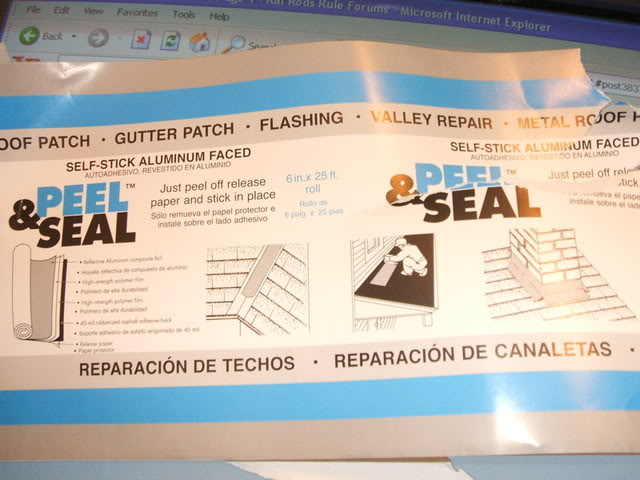

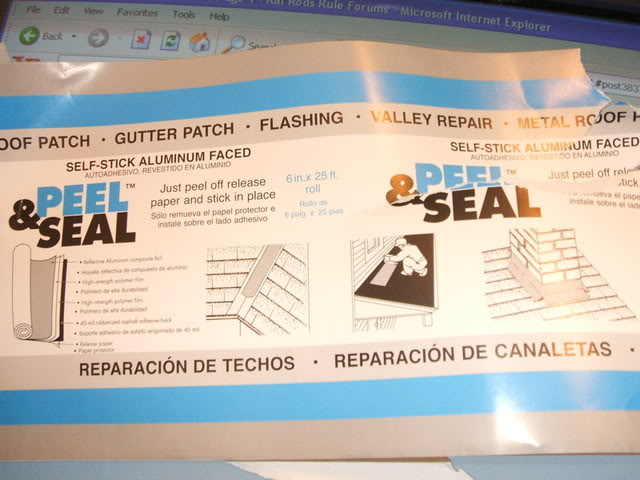

Peel & Seal is the cheap alternative to Dynamat. This is the stuff you get from Lowes Hardware. It is the same as the original Dynamat but a lot cheaper.

I started putting my fake Dynamat down. This is the stuff that they have been talking about on HAMB and a few other forums. I paid less than $15.00 for a 6in. X 24ft. roll. It's very, very close to Dynamat other than the price. It has a 40 mil rubberized aspalt sticky back, two layers of high stregth polymer film over a reflective aluminum surface.

Any

I was worried a little about how good it would stick. I pre cut what I needed then I used a heat gun on the backing. Let me tell you!! When you stick it on you can't get it off. Even if it just bearley touches it. Make sure you have it all lined up before you touch anything with the backing.You can use a wall paper wheel to smooth it out. I didn't have one so I used an unopen pop can. As you can see from the bead rolls in the floor it takes the shape of where up put it. Cool thing is this stuff is used for flashing and as a roof patch. Any small holes you may have this will seal them and not let the water in. They do sell a better version of the Dynamat. It is the sound and heat Dynamatt. It is almost twice as thick as the original. No problem. For the price difference put a second layer over this one. Even with the floor half done I can tell a difference in how it sounded when I close the truck door.

this may help you if you go looking for it..

If you can't find it at your local hardware here's a link where you can order it. http://www.abccatalog.com/store/viewitem.asp?idproduct=2579952312

I started putting my fake Dynamat down. This is the stuff that they have been talking about on HAMB and a few other forums. I paid less than $15.00 for a 6in. X 24ft. roll. It's very, very close to Dynamat other than the price. It has a 40 mil rubberized aspalt sticky back, two layers of high stregth polymer film over a reflective aluminum surface.

Any

I was worried a little about how good it would stick. I pre cut what I needed then I used a heat gun on the backing. Let me tell you!! When you stick it on you can't get it off. Even if it just bearley touches it. Make sure you have it all lined up before you touch anything with the backing.You can use a wall paper wheel to smooth it out. I didn't have one so I used an unopen pop can. As you can see from the bead rolls in the floor it takes the shape of where up put it. Cool thing is this stuff is used for flashing and as a roof patch. Any small holes you may have this will seal them and not let the water in. They do sell a better version of the Dynamat. It is the sound and heat Dynamatt. It is almost twice as thick as the original. No problem. For the price difference put a second layer over this one. Even with the floor half done I can tell a difference in how it sounded when I close the truck door.

this may help you if you go looking for it..

If you can't find it at your local hardware here's a link where you can order it. http://www.abccatalog.com/store/viewitem.asp?idproduct=2579952312

RebStew- Scrounger's Pitbull On Nitrous

- Number of posts : 12420

Registration date : 2007-10-09

Age : 95

Location : Newport Ky

Re: Penny Pinching Tech Tips.

Re: Penny Pinching Tech Tips.

I bought a new welder not long ago. I still have my old one and it works for small stuff so I didn't want to unbolt it from the welding cart. I have been dragging the new welder around on the floor. The other day a shopping cart popped up at the house. There is one in my alley almost weekly  So anyway I came across this double decker short cart. two baskets on it. I got to look at it and before I could stop myself here what we ended up with.

So anyway I came across this double decker short cart. two baskets on it. I got to look at it and before I could stop myself here what we ended up with.

The top basket cut off.

The swing out was flip over and used to hold my body hammers and dollies. Clamps are on the side. Place for the helmets and room on the sides of the welder for welding gloves, aprons ect ect

The top basket cut off.

The swing out was flip over and used to hold my body hammers and dollies. Clamps are on the side. Place for the helmets and room on the sides of the welder for welding gloves, aprons ect ect

Reb Stew- National President

- Number of posts : 7905

Registration date : 2012-04-08

Age : 104

Location : Looking in your window

Re: Penny Pinching Tech Tips.

Re: Penny Pinching Tech Tips.

Welding bottle caps make great hammer heads for forming sheet metal. Bowling balls, and trailer hitch balls are great to planish metal on. And sections of old leaf springs make really good slapping hammers. All these can be found on the cheap. Harbor freight pry bars can be welded together for a nice tucking tool.

Chris55- FL Chapter President

- Number of posts : 1360

Registration date : 2010-04-16

Age : 58

Location : Geneva, Florida

Re: Penny Pinching Tech Tips.

Re: Penny Pinching Tech Tips.

Ok, how did you 'acquire' that shopping cart? I see 'em at Kroger all the time.

mpvance- Car washer

- Number of posts : 26

Registration date : 2011-05-27

Age : 64

Location : Central KY

Re: Penny Pinching Tech Tips.

Re: Penny Pinching Tech Tips.

RebStew wrote:

We had suede or flat color paint long before it was in style. Why? Becuse we got tire of grey, black or red primered cars. I remember trying to get ready to take the T bird to TN and was primering it. I had some red and blue paint from a guys car I painted. I tossed it in with the grey primer and we ended up with a purple suede 65 T bird.

man i liked the "PURPLE PEOPLE EATER"

JRiggs- Scrounger

- Number of posts : 3505

Registration date : 2007-10-09

Age : 44

Location : erlanger ky

Re: Penny Pinching Tech Tips.

Re: Penny Pinching Tech Tips.

I dig that welding cart. How stable do you think it would be with a 80 cf. bottle on the back, modified of course? Looks like it would need more weight on the front.

DEMONSPEED- Scrounger

- Number of posts : 420

Registration date : 2009-05-30

Age : 29

Location : Interzone

Re: Penny Pinching Tech Tips.

Re: Penny Pinching Tech Tips.

Not sure. It's pretty stable as is. You could always use a bigger cart.

Reb Stew- National President

- Number of posts : 7905

Registration date : 2012-04-08

Age : 104

Location : Looking in your window

Re: Penny Pinching Tech Tips.

Re: Penny Pinching Tech Tips.

I seen this on another forum and had to share. I'm going to make one. Paint can shaker. Yea I know it's the lazy way out.

Reb Stew- National President

- Number of posts : 7905

Registration date : 2012-04-08

Age : 104

Location : Looking in your window

Re: Penny Pinching Tech Tips.

Re: Penny Pinching Tech Tips.

That and one of those trigger sprayers. Life is GOOD!

Brownie- Scrounger

- Number of posts : 941

Registration date : 2011-11-30

Age : 53

Location : Port Charlotte Florida

Re: Penny Pinching Tech Tips.

Re: Penny Pinching Tech Tips.

Love that paint shaker. Gotta make one now.

Couldn't find a back up light switch for my '69 Mach I that I could justify the price, that had the bracket with it, so bent a piece of 18 gauge to hook over the shifter bolt, drilled it to fasten a Jacobs engine brake micro switch to it (you could rob {borrow} one of these out of just about any heavy truck salvage yard), lined it up and bent the bracket so that when the reverse lever comes back to the reverse position, it pushes the button on the micro switch and powers the backup lights. I think it cost me a grand total of about 6 feet of 16 gauge wire to run from the firewall connector down to the trans shifter to get backup lights working. And a couple of bullet connectors. I could go on for hours 'splaining the special tools for large engine overhaul that myself and a couple other guys have built to avoid paying out long dollars to do something on the cheap, or in the field when we didn't have the time to wait 4 days for something to be shipped in. Sometimes it isn't the cost, it is the investment of time waiting for stuff to show up- and if you don't have the time, you start on your own making what will work.

Couldn't find a back up light switch for my '69 Mach I that I could justify the price, that had the bracket with it, so bent a piece of 18 gauge to hook over the shifter bolt, drilled it to fasten a Jacobs engine brake micro switch to it (you could rob {borrow} one of these out of just about any heavy truck salvage yard), lined it up and bent the bracket so that when the reverse lever comes back to the reverse position, it pushes the button on the micro switch and powers the backup lights. I think it cost me a grand total of about 6 feet of 16 gauge wire to run from the firewall connector down to the trans shifter to get backup lights working. And a couple of bullet connectors. I could go on for hours 'splaining the special tools for large engine overhaul that myself and a couple other guys have built to avoid paying out long dollars to do something on the cheap, or in the field when we didn't have the time to wait 4 days for something to be shipped in. Sometimes it isn't the cost, it is the investment of time waiting for stuff to show up- and if you don't have the time, you start on your own making what will work.

dieseldr- Hot Rod Builder

- Number of posts : 603

Registration date : 2011-03-20

Age : 61

Location : Western NY

Re: Penny Pinching Tech Tips.

Re: Penny Pinching Tech Tips.

dieseldr wrote: I could go on for hours 'splaining the special tools for large engine overhaul that myself and a couple other guys have built .

Well, Start 'splaining! Home made tools are wonderfully adaptable.

Arieldouglas- TN Chapter President

- Number of posts : 1915

Registration date : 2011-07-03

Age : 65

Location : Watertown, TN

Re: Penny Pinching Tech Tips.

Re: Penny Pinching Tech Tips.

Reb Stew wrote:I seen this on another forum and had to share. I'm going to make one. Paint can shaker. Yea I know it's the lazy way out.

I love this! I hate shaking rattle cans.

Arieldouglas- TN Chapter President

- Number of posts : 1915

Registration date : 2011-07-03

Age : 65

Location : Watertown, TN

Re: Penny Pinching Tech Tips.

Re: Penny Pinching Tech Tips.

A lot of the stuff we built was for big iron, stuff like slings to put pistons in, using large snap ring pliers for piston ring expanders, grinding the head of a bolt down thin but with a radius on it so you could stick it in the crankshaft oil hole after the main cap is removed and then you rotate the crank with the specially ground bolt in the oil hole to "roll out" and "roll in" the main bearing inserts in the block, using paper (cardboard) matchsticks to wedge into the corners of a detroit diesel cyl head peripheral oil seal so it doesn't pop out on you when you set the head on, blah, blah, blah....... lotsa stuff that doesn't pertain to daily mechanical chores for automobiles...... how many more you want?

dieseldr- Hot Rod Builder

- Number of posts : 603

Registration date : 2011-03-20

Age : 61

Location : Western NY

Re: Penny Pinching Tech Tips.

Re: Penny Pinching Tech Tips.

Redneck 4 wheel toe in alignment for anti- cue vehicles--

Materials required..... 2 cinder (cement) blocks

Kite string

Measuring device

Place the blocks (or other heavy device) in front of the vehicle about 5 feet out front of each wheel. Tie the kite string to one block, walk around the rear of the vehicle with the string and come back to the front on the opposite side you started. Walk back to the rear axle without the string, and when you get to the rear end you will pull it tight down one side of the car, set it against the rear tire sidewall about 2/5 up the height of the tire, hold tension on it, do the same on the other rear wheel, keep tension on the string, walk to the last wheel up front and tie the string to the block with tension on the string. The trick is to keep the string tight, if it goes slack it falls to the floor and you start over. Align the string along the rear sidwalls until it just touches the sidewall on the front of the rear tire- do this by sliding the blocks sideways to get the string where you want it on the rear sidewall. This will be your reference to measure front toe in from--- see where I'm going with this? Once the string is set to straight ahead on the rear wheel sidewall, this is your reference to find zero toe for the front end off a measurement from the string to the front tire side wall. By the way, most vehicles usually run 1/16 to 3/16 toe in. And remember, on 1/8 toe total, split it between both fronts.... 1/16 each. Set your preload through center in the steering gear, center your steering wheel, then do the "string alignment", and you should end up with a car that runs down the road fairly straight, the steering wheel fairly straight, or at least close enough you can now fine tune it. Now if your caster/camber is off, this won't help a bit, but if you put all new tie rods, ends, drag links, etc on and want to get it so you can drive it, this will work.... it may surprise you just how good it does work. I find it to be much more accurate than the old "scuff boards" we used to have to use for NYS inspection, (which used to read side scuff in inches or feet per mile) and as accurate as anything anybody else has been using around here.

Materials required..... 2 cinder (cement) blocks

Kite string

Measuring device

Place the blocks (or other heavy device) in front of the vehicle about 5 feet out front of each wheel. Tie the kite string to one block, walk around the rear of the vehicle with the string and come back to the front on the opposite side you started. Walk back to the rear axle without the string, and when you get to the rear end you will pull it tight down one side of the car, set it against the rear tire sidewall about 2/5 up the height of the tire, hold tension on it, do the same on the other rear wheel, keep tension on the string, walk to the last wheel up front and tie the string to the block with tension on the string. The trick is to keep the string tight, if it goes slack it falls to the floor and you start over. Align the string along the rear sidwalls until it just touches the sidewall on the front of the rear tire- do this by sliding the blocks sideways to get the string where you want it on the rear sidewall. This will be your reference to measure front toe in from--- see where I'm going with this? Once the string is set to straight ahead on the rear wheel sidewall, this is your reference to find zero toe for the front end off a measurement from the string to the front tire side wall. By the way, most vehicles usually run 1/16 to 3/16 toe in. And remember, on 1/8 toe total, split it between both fronts.... 1/16 each. Set your preload through center in the steering gear, center your steering wheel, then do the "string alignment", and you should end up with a car that runs down the road fairly straight, the steering wheel fairly straight, or at least close enough you can now fine tune it. Now if your caster/camber is off, this won't help a bit, but if you put all new tie rods, ends, drag links, etc on and want to get it so you can drive it, this will work.... it may surprise you just how good it does work. I find it to be much more accurate than the old "scuff boards" we used to have to use for NYS inspection, (which used to read side scuff in inches or feet per mile) and as accurate as anything anybody else has been using around here.

dieseldr- Hot Rod Builder

- Number of posts : 603

Registration date : 2011-03-20

Age : 61

Location : Western NY

Reb Stew- National President

- Number of posts : 7905

Registration date : 2012-04-08

Age : 104

Location : Looking in your window

Re: Penny Pinching Tech Tips.

Re: Penny Pinching Tech Tips.

Well, here's my silly contribution...

SOS pads work incredibly well to clean up any cast metal parts. And it gets it done FAST! Keep it off of chrome or billet aluminum though.

Later,

Lee

SOS pads work incredibly well to clean up any cast metal parts. And it gets it done FAST! Keep it off of chrome or billet aluminum though.

Later,

Lee

Nanook- Scrounger

- Number of posts : 1088

Registration date : 2010-06-28

Age : 52

Location : Walton, KY

Re: Penny Pinching Tech Tips.

Re: Penny Pinching Tech Tips.

Off topic, but, I see your signature and the Super Duty remark... no greater factory racers were ever built, but my mind can't help but try to remember when Ford used "super duty" on their medium/heavy trucks back in the day. I almost think it was '59, can anyone shed some light on this? Not trying to start anything, but just curious when that designation came about on the Ford trucks. Of course, over the years Ford stopped using it, and picked it up later in life. Sorry for hijacking the thread, but trying to get a little history lesson here. Thanks all.

dieseldr- Hot Rod Builder

- Number of posts : 603

Registration date : 2011-03-20

Age : 61

Location : Western NY

Re: Penny Pinching Tech Tips.

Re: Penny Pinching Tech Tips.

dieseldr wrote:Off topic, but, I see your signature and the Super Duty remark... no greater factory racers were ever built, but my mind can't help but try to remember when Ford used "super duty" on their medium/heavy trucks back in the day. I almost think it was '59, can anyone shed some light on this? Not trying to start anything, but just curious when that designation came about on the Ford trucks. Of course, over the years Ford stopped using it, and picked it up later in life. Sorry for hijacking the thread, but trying to get a little history lesson here. Thanks all.

Ford came out with 3 new V8 gas engines of 401, 477 and 534 CID for their big truck lines in 1958 and labeled them Super Duty. These engines were found in those tilt cab C.O.E. tractors that Ford made so many of up into at least the mid '60's and they probably were used in the normal (not flat fronted) tractors too. In the book I am getting this info from (Ford Spotter's Guide 1920-1992) the last Super Duty Reference as it pertains to big trucks is with the '62 models but that doesn't mean that it's use stopped then.

Now let's get back to saving some $$$

Truxter Fordly- OH Chapter President

- Number of posts : 424

Registration date : 2009-10-21

Age : 65

Location : Loveland, OH

Re: Penny Pinching Tech Tips.

Re: Penny Pinching Tech Tips.

Ive been prowling around here for a while now, figured id toss in a few of my favorites.

1) I use an aluminum heat sink sourced from a frequency drive for plug welding old trim holes. Hold the flat side on the outside of the panel, and there's virtually no grinding, as the weld will not adhere to the aluminum, and if you're quick about it the sheetmetal wont get hot enough to warp.

2) You can tear down an old distributor to build an oil pump priming tool.

3) Chevrolet Vortech trucks with the 5.7, 5.0, and 4.3 liter engines have mini starters that work well with Gen I smallblocks that have headers. Theyre usually $30 something at the junkyard.

4) Late 90's Mercury Mountaineer and V8 Ford Explorers are very common in the you pull yards, and came equipped with the GT-40 302 engines. That makes for a very fair priced roller engine for your project. If nothing else, nab the GT-40P heads for your older 302.

5) F Series gas burners and Broncos from 86 through 96 I think use an inline fuel pump in addition to the in tank pump. It has more than enough pressure and volume to feed my TBI V8, it'll feed your carbed motor. I've never gave more than $10 for one with the harness at the junkyard.

6) GM's TBI engines are notorious for running rich, mostly due to the fact that the O2 sensors never get warm enough to enter closed loop operation. This is why most of them have Service lights on. Replace the one or two wire oxygen sensors with a heated three wire sensor from a 94 or later fullsize truck. Stay away from the four wire variety.

7) Shorten your own driveshaft? Balance it yourself. Drill a hole and tap it to accept a zerk fitting. Load 'er down with grease and drive . The grease will sling around the inside and balance itself. Not 100%, but its close enough for the girls I run with!

1) I use an aluminum heat sink sourced from a frequency drive for plug welding old trim holes. Hold the flat side on the outside of the panel, and there's virtually no grinding, as the weld will not adhere to the aluminum, and if you're quick about it the sheetmetal wont get hot enough to warp.

2) You can tear down an old distributor to build an oil pump priming tool.

3) Chevrolet Vortech trucks with the 5.7, 5.0, and 4.3 liter engines have mini starters that work well with Gen I smallblocks that have headers. Theyre usually $30 something at the junkyard.

4) Late 90's Mercury Mountaineer and V8 Ford Explorers are very common in the you pull yards, and came equipped with the GT-40 302 engines. That makes for a very fair priced roller engine for your project. If nothing else, nab the GT-40P heads for your older 302.

5) F Series gas burners and Broncos from 86 through 96 I think use an inline fuel pump in addition to the in tank pump. It has more than enough pressure and volume to feed my TBI V8, it'll feed your carbed motor. I've never gave more than $10 for one with the harness at the junkyard.

6) GM's TBI engines are notorious for running rich, mostly due to the fact that the O2 sensors never get warm enough to enter closed loop operation. This is why most of them have Service lights on. Replace the one or two wire oxygen sensors with a heated three wire sensor from a 94 or later fullsize truck. Stay away from the four wire variety.

7) Shorten your own driveshaft? Balance it yourself. Drill a hole and tap it to accept a zerk fitting. Load 'er down with grease and drive . The grease will sling around the inside and balance itself. Not 100%, but its close enough for the girls I run with!

Kentucky Kid- S.W. Ky Chapter President

- Number of posts : 119

Registration date : 2011-03-16

Age : 38

Location : Paducah, KY

Re: Penny Pinching Tech Tips.

Re: Penny Pinching Tech Tips.

Cool stuff

Reb Stew- National President

- Number of posts : 7905

Registration date : 2012-04-08

Age : 104

Location : Looking in your window

Re: Penny Pinching Tech Tips.

Re: Penny Pinching Tech Tips.

I built a leaf spring re-archer with a 10 ton bottle jack and some square tubing. It works really well. I re-arched the front springs on my sons 67 dodge d100.

307Merc- new kid on the block

- Number of posts : 7

Registration date : 2015-12-04

Age : 47

Location : Casper, WY

Re: Penny Pinching Tech Tips.

Re: Penny Pinching Tech Tips.

any pictures. I have a pick up that needs the springs re-arched

Salty Dog- new kid on the block

- Number of posts : 2

Registration date : 2015-11-10

Re: Penny Pinching Tech Tips.

Re: Penny Pinching Tech Tips.

I can't get pictures to upload on here. Send me your cell number or e mail and I can send you some.

307Merc- new kid on the block

- Number of posts : 7

Registration date : 2015-12-04

Age : 47

Location : Casper, WY

Re: Penny Pinching Tech Tips.

Re: Penny Pinching Tech Tips.

Email my son. 911tazz@gmail.com thank you.

911TAZZ- Scrounger

- Number of posts : 715

Registration date : 2011-11-12

Age : 55

Location : cincinnati

Permissions in this forum:

You cannot reply to topics in this forum|

|

|